The technical team has been engaged in the preparation of rare metal spherical powders and the production of high-performance powder metallurgy products for a long time.

Saisu uses high-purity argon gas atomization and plasma rotating electrode atomization technology to prepare high-quality spherical rare metal powders, including titanium alloys, Ti Al alloys, Ti2AlNb, Ti Ta alloys, Ti Nb (- Zr) alloys, niobium alloys, tantalum alloys, etc. The powder has low oxygen content, high sphericity, good flowability, and stable performance, which can well meet the different needs of processes such as electron beam powder 3D printing, laser powder 3D printing, and laser coaxial powder feeding 3D printing.

Types of powder that can be produced:

TiAl powder: Ti48Al2Cr2Nb, Ti2AlNb, Ti45Al8Nb

Titanium alloy powder: CP Ti, TC4, TC4ELI, TA7ELI, TC11

Medical powders: TiTaNbZr, TiNbZr, NiTi, CoCrMo

Refractory, high entropy alloy powders: Stellite, Nb521, Ti Ta, Ta, W

Typical spherical metal powders prepared by PREP method

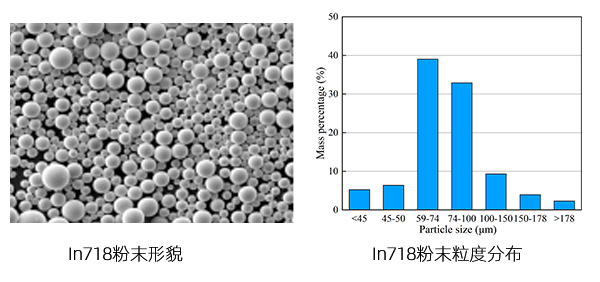

Inconel718 powder for aerospace applications

Chemical composition (Inconel718)

| Elements | Cr | Ni | Nb | Al | Ti | Co | C | O

| N | Si |

| Wt.% | 19.20 | 51.84 | 5.11 | 3.28 | 0.45 | 0.89 | 0.037 | 0.007 | 0.003 | 0.20 |

Physical properties of powder: Sphericity rate:>90% Particle size:<74 μ m Powder percentage ≥ 50% Liquidity: 14s/50g Loose density: 4.91g/cm3 Solid density: 5.35/cm3 Basically no irregular powder or satellite powder |  |

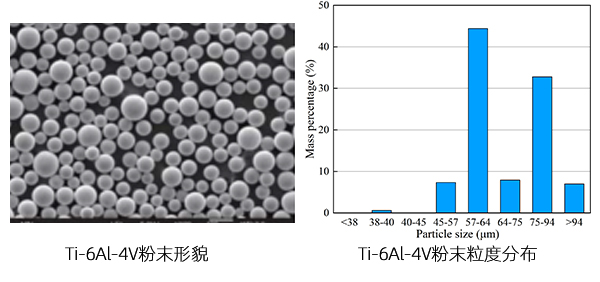

SEBM uses Ti-6Al-4V powder

Chemical composition (Ti-6Al-4V)

| Elements | Al | V | C | Fe | O | N | H | Ti |

| Wt.% | 6.46 | 4.33 | 0.02 | 0.2 | 0.078 | 0.02 | 0.002 | Bal |

Physical properties of powder: Sphericity rate:>90% Particle size: D50 ≈ 70 μ m Liquidity: 27s/50g Loose density: 2.65g/cm3 Solid density: 2.86/cm3 Basically no irregular powder or satellite powder |  |

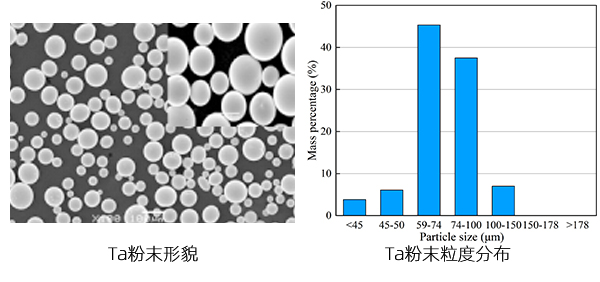

Tantalum powder for biomedical applications

chemical composition

| 元素 | C | O | N | H | Nb | Fe | Ti

| W | Mo | Si | Ni | Ta |

| YY/T0966 | 100 | 300 | 100 | 15 | 1000 | 100 | 100 | 50 | 20 | 5 | 100 | Bal. |

| 赛隆钽粉 | 10 | 50

| 30 | 10 | <10 | 30 | 10 | <30 | <20 | <30 | 10 | Bal. |

Physical properties of powder: Sphericity rate:>90% Particle size:<105 μ m Liquidity: 7.5S/50g Loose density: 9.3g/cm3 Vibration density: 9.8/cm3 Basically no irregular powder or satellite powder |  |

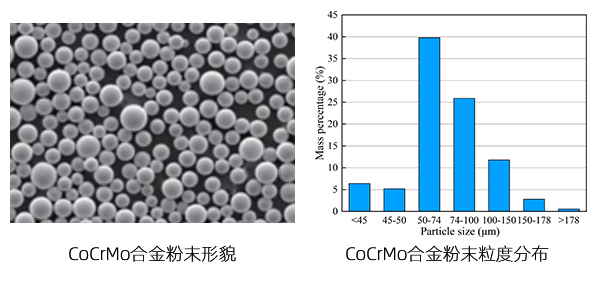

CoCrMo alloy powder for biomedical applications

Chemical composition (CoCr28Mo6)

| Elements | Cr | Mo | Ni | Fe | C | Mn | Si | O | Co |

| Wt.% | 28.75 | 6.57 | 0.52 | 0.08 | 0.18 | 0.002 | 0.02 | 0.03

| Bal. |

Physical properties of powder: Sphericity rate:>90% Particle size:<74 μ m Powder percentage ≥ 50% Liquidity: 12s/50g Loose density: 5.17g/cm3 Solid density: 5.62/cm3 Basically no irregular powder or satellite powder

|  |

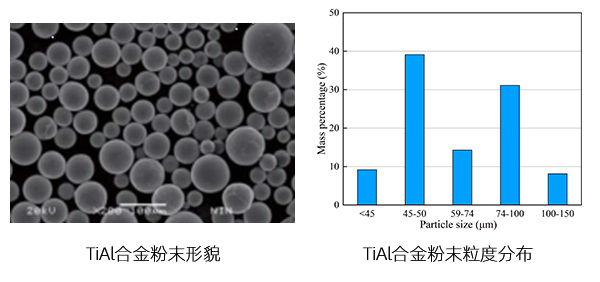

TiAl (4822) powder for aerospace powder metallurgy and SEBM

Chemical composition (Ti-48Al-2Nb-2Cr (at.%)/Ti-32.4Al-4.76Nb-2.66Cr (wt.%))

| Elements | Al | Nb | Cr | O | N | C | H |

| Wt.% | 33.5 | 4.81 | 2.71 | 0.08 | 0.008 | 0.008 | 0.001 |

Physical properties of powder: Sphericity rate:>90% Particle size: D50 ≈ 100 μ m Liquidity: 24s/50g Loose density: 2.53g/cm3 Solid density: 2.59/cm3 Basically no irregular powder or satellite powder

|  |

TiAl powder for aerospace powder metallurgy and SEBM

Chemical composition (Ti-45Al-7Nb-0.3W (at.%)/Ti-28.8Al-15.4Nb-1.3W (wt.%))

| Elements | Al | Nb | W | O | N | C | H |

| Wt.% | 28.3 | 15.0 | 1.27 | 0.09 | 0.008 | 0.008 | 0.001 |

Physical properties of powder: Sphericity rate:>90% Particle size: D50 ≈ 80 μ m Liquidity: 29s/50g Loose density: 2.57g/cm3 Vibration density: 2.61/cm3 The powder has high sphericity and there are basically no irregular powders, satellite powders, or hollow powders The chemical composition can be supplemented or added with individual elements according to user needs, such as Al and W

|  |